Cider - Profi production lines

Production lines CIDERLINE PROFI – Recommended basic configurations of professional alkoholic cider production lines.

Cider - Modulo production lines

Production lines CIDERLINE MODULO – Recommended basic configurations of modular alkoholic cider production lines.

Fruit rinsing equipment

Equipment for rinsing of fruit before its crushing and pressing to be produced fruit beverages.

Fruit crushing equipment

Equipment for crushing of fruit before its pressing in the beverage production process.

Fruit pressing equipment

Equipment for pressing of crushed fruit in the fruit beverage production process.

Fruit manipulation equipment

Equipment for manipulation with fruit before and within the fruit processing.

Pumps for fruit mash

Special pumps for transportation of pressed fruit mash to the fermentation tanks.

Mixing-homogenizing tanks

Tanks with the mixer for mixing and homogenizing of honey or fruit mash or must.

Scales for raw material

Scales for the weighing of the raw material - fruit and other ingrediences to production of alcoholic cider.

Primary fermentation tanks for cider

Tanks for the primary fermentation of cider. Cylindrically-conical fermenters, cylindrical fermenters, insulated and non-insulated fermentation tanks.

Secondary fermentation tanks for cider

Tanks for the secondary fermentation of cider - the cider maturation process under pressure. Cylindrical maturation tanks, cylindrically-conical tanks, insulated and non-insulated fermenters.

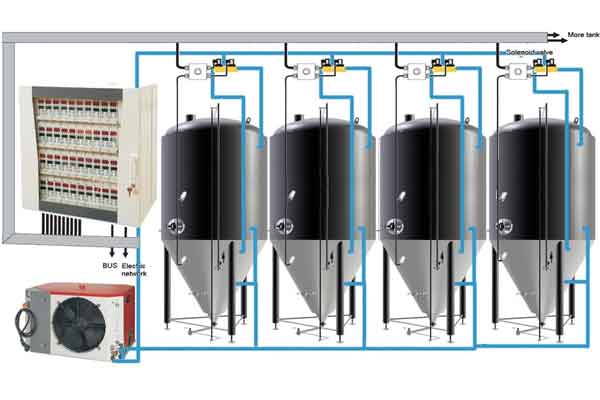

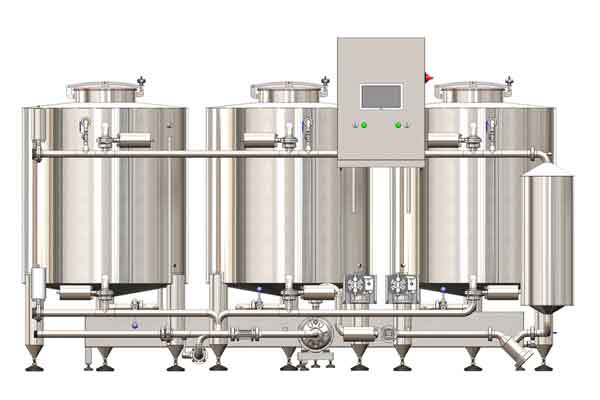

Complete fermentation sets

Fully equipped sets for the fermentation and maturation of cider under pressure that are equipped with classical cylindrical-conical tanks and all equipment for controlled cooling of the tanks.

Yeast processing equipment

Equipment to safety storage, revitalization, collecting and dosage of yeast. Yeast storage and regeneration tanks, yeast propagation stations. Bottles for storage yeast.

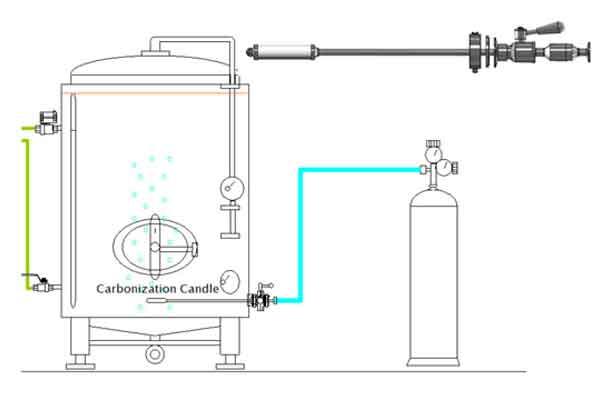

Conditioning tanks

Special pressure tanks for the conditioning of alkoholic cider. Conditioning tanks are used for the carbonization of cider, additional flavourization, filtration, filling cider beverages into bottles, kegs, cans.

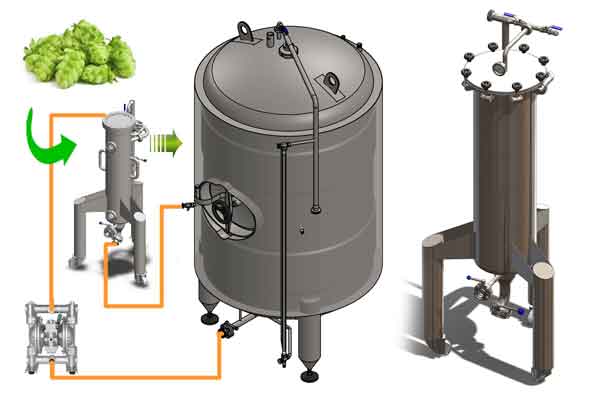

Flavoring equipment

Equipment for extraction of aromatic active substances from solid ingrediences to finalized cold cider after finalizing the fermentation process.

Carbonization equipment

Equipment for carbonization of cider in the pressure cider conditioning tanks or in the pipes under pressure using an external carbondioxide pressure cylinders.

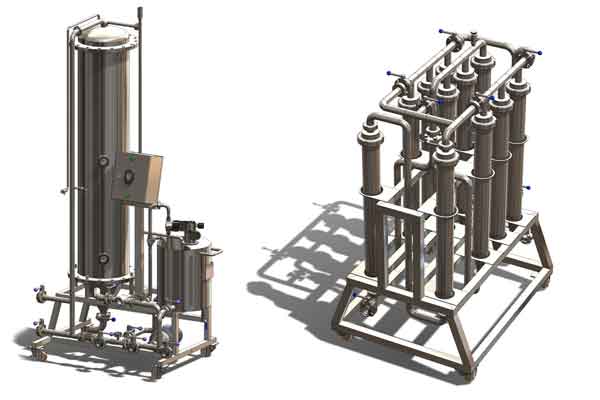

Filtration equipment

Equipment for filtration of cider. Plate filters, diatomaceous filters, cross-flow filters, microfilters. Mechanical reduction of yeast in cider.

Pasteurization equipment

Equipment for pasteurisation of cider. The pasteuriser is an integral part of the cider production process.

Filling into kegs

Equipment for filling of carbonated alcoholic beverages into stainless steel barrels - kegs. Rinsing, cleaning, sanitizing and filling of the kegs.

Filling into petainers

Equipment for filling of carbonated alcoholic beverages into plastic kegs - petainers.

Filling into cans

Equipment for the filling of carbonated alcoholic beverages into into aluminium cans and for the capping of cans.

Filling into glass bottles

Equipment for the filling of carbonated alcoholic beverages into into glass bottles. Rinsing, cleaning, filling, capping and labelling of glass bottles.

Filling into PET bottles

Equipment for the filling of carbonated alcoholic beverages into into PET bottles. Capping and labelling of PET bottles.

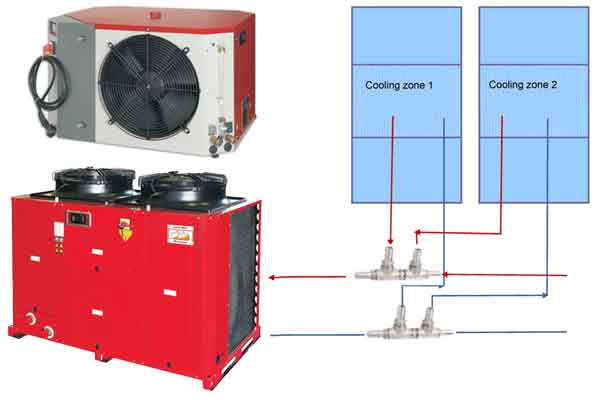

Cooling systems

The cooling systems include equipment for cooling of tanks and other components to storage, fermentation, distribution of cider and yeast.

Heating systems

Heating machines intended to heating up the fruit juice before start of the fermentation process.

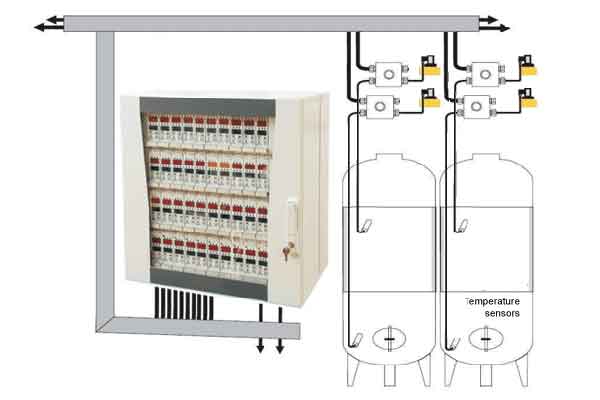

Measuring & Control systems

Systems serve to manual or automatic control of the temperatures in the tanks and control of other equipment.

Cleaning & sanitizing systems

Static and mobile CIP stations to cleaning, sanitizing, sterilization of the tanks, pipes, hoses and other equipment.

Beverage dispensing equipment

Equipment for dispensing of beverage into glasses, storage, cooling and transport beverage before its serving into glasses.

Compressed air system

Equipment for cleaning, drying, compressing and distribution of sterile compressed air to pneumatic valves, actuators and flotation of cider.

Nitrogen system

Equipment for production of sterile nitrogen from compressed air to pressurizing of tanks during filtration, dispenzing or transport of cider.

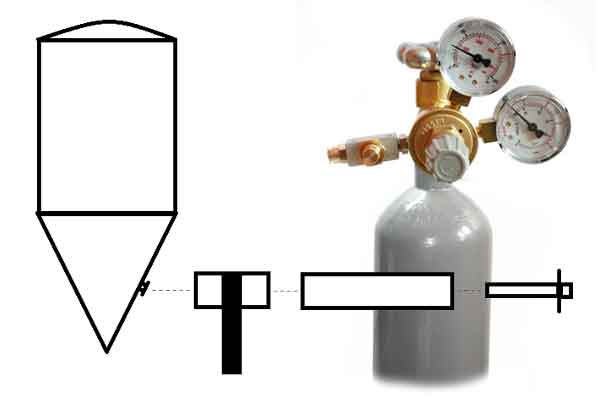

Carbondioxide system

Equipment for dosing, regulation and transport of carbondioxide to pressurizing of tanks during filtration, dispenzing or transport of cider.

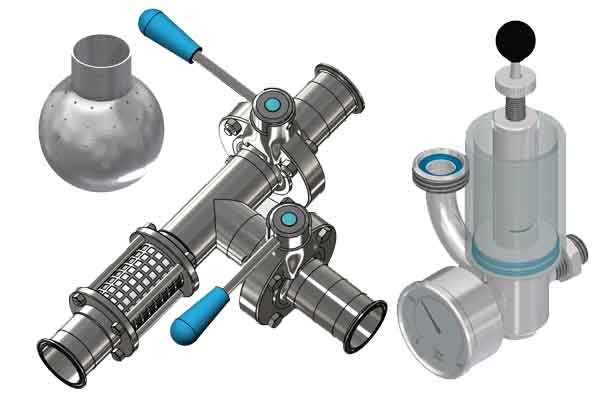

Pumps

Pumps for transport cider, water, sanitizing solutions, wort, for the extraction ingrediences into cider and other purposes.

Tank equipment & accessories

Optional equipment, accessories, tools and auxiliary equipment for cider production tanks.